Offline XRay Counter

Keyword:

HSTECH

hiddenValue

- Technical Parameter

- Description and Features

- Application

-

Product name

Offline X-Ray SMD Counter

Model

DS-3000

X Ray Tube

Type

Enclose type, micro focal spot

Tube voltage

80kV

Tube current

700μA

Focal spot size

30μm

Flat-table testing probe

Type

HD digital table

Effective area

430*430mm

Pixel size

140μm

Resolution

3072*3072

Tape reel

Max size

17 inch(approx 430mm)

Max height

85mm

Min components

01005

Counting speed

10 seconds each time

Counting accuracy

>99.95%

Functions

Bar-code auto scanning

Support QR code,bar-code

Label printer

Print corresponding label

Management system

MES,ERP,WMS

Machine basic information

Size

1067*1335*1968mm

Weight

950KG

Power supply

AC110V/220V,50/60Hz

Max power

800W

Industrial PC

I7-6700 CPU, 8G RAM, 240GB SSD

Monitor

24inch HDMI display

Security

Radiation

None,standard <1uSv/hr

Rear side door lock

Once open the door, the X ray tube power off immediately

Table anti-collision protection

When the table extended, there is a steel plate around it to prevent deformation by impact

Safety grating

Equipped

Emergency button

Equipped

-

Introduction:

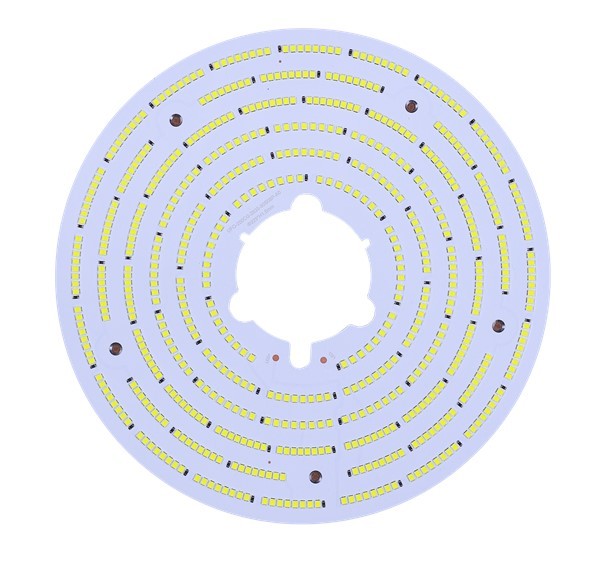

This unit offline X ray SMD counting machine is a semi-automatic SMD counting machine, manual load the tape reels on the testing table,press the start button, then the machine will scan the reels and display the image and quantity of chips automatically,at the same time transfer the data to the label printer, operator can paste the new label on the reels with correct chip quantity information.

Features:

- The X-ray source adopts 80KV enclosed X-ray tube, stable quality, don’t need maintenance.

- Use public company Shanghai IRay,17-inch ultra-clear digital flat-panel X ray detecting probe, eliminates the traditional scanning detectors.

- Ultra fast counting, scan 4 pcs 7 inch reel or 1 pc 15 inch reel only need 10 seconds.

- Max can count 17inch (430mm)tape reel, including the a moisture-proof bag or Jedec packed tape reels.

- The patent deep learning algorithm with independent property rights, accumulate data to the cloud database and share it with all machines.

6. The machine will scan the bar-code and counting the reels at the same time, don’t need manual scan the bar-code, and the corresponding label will be printed immediately when any reel is taken out, without mistakes.

7. The machine will scan the bar-code and counting the reels at the same time, don’t need manual scan the bar-code, and the corresponding label will be printed immediately when any reel is taken out, without mistakes.

8. Support the docking of MES, ERP, WMS and other systems, and digitally manage the material warehouse. Software algorithm is permanently updated.

9. Compared with traditional counting machine, it greatly improves the efficiency and accuracy, saves manpower, and greatly shortens the time of material in and out of the warehouse.

Related Product

Send Inquiry

NOTE: Please leave your email, our professional person will contact you asap!